With anti-reflective coatings and mirror coatings, the relationship (marriage) between the lens, the hardcoat and the coatings are often misunderstood. In this discussion, I would like to delve a little more deeply into the relationship between the hardcoat and the coatings. My hope is that by understanding this relationship, we can better arm everyone to make decisions when choosing to pair a particular lens (with all of its characteristics) with a particular coating (AR or mirror and their characteristics).

Anti-reflective coatings and mirror coatings are considered “thin films”. These coatings are measured by the nanometer. They are usually organic in nature, hard (relatively speaking), and robust; but at the end of the day, they are THIN. There are many things that go into making a great thin film coating. None is more important than the foundation under it: Hardcoating.

Hardcoating is generally referred to as a “thick film”. Hardcoats are normally microns thick. The hardcoat will serve as the intermediary between the lens and the Thin Film. Hardcoats are usually inorganic, formable, pliable, and increase scratch resistance.

Here is a microscopic view of the two coatings. In this image, you can see the size differential relative to one another.

There are several different types of hardcoats: siloxanes, acrylics, and urethanes. There are also several different application techniques: spin, dip, flow and spray. Each one of these techniques and types has its pluses and minuses. What we are mainly concerned about for the application of thin films are these three factors: hardness, cure and refractive index.

Hardness

The thin film can be very hard, but because it is so thin, the resultant abrasion resistance will be an additive effect of the hardcoat plus the thin film. If the hardcoat is soft, the resultant abrasion resistance will be poor. This is due in large part to the thinness of the thin film. It cannot overcome a negative quality in the hardcoat. For this reason, hardcoats that have a high abrasion resistance are usually a preferable foundation for a thin film. These hardcoats are usually siloxanes or siloxane blends. They have a high silicon content and are therefore relatively very hard. Poly-siloxane hardcoats are typically the hardest, and urethanes are typically the softest of the hardcoats.

Cure

Many, many thin film coatings are damaged or destroyed by this factor and that is why I have included it here. When a hardcoat is applied, it is a certain size. As the hardcoat is cured, it shrinks in size. When the thin film is applied, it is in its final form; its size will not change. At this interface between the organic thin film and the inorganic hardcoat, it is imperative that the hardcoat not change size or shape or the AR will buckle, making the hardcoat cure a very important factor. Below is an image of an AR coating that buckled due to shrinkage in the hardcoat.

As you can probably make out, the thin film had a specific size and was attached to the hardcoat. As the hardcoat continued to cure and shrink, the compressive stress exceeded the adhesive strength of the thin film to the hardcoat; causingit to buckled; the thin film will eventually break.

Refractive Index

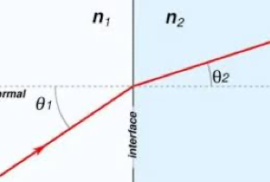

For the best optical performance on the lens, all three materials (lens, hardcoat, thin film) should be index matched. Each time light comes in contact with a surface, it will refract. If each material has the same index of refraction, you will see no change in the transmitted or reflected light (visible to the eye). But, if the index of refraction is different from lens to hardcoat, birefringence will be seen. This rainbow effect cannot be overcome by the thin film and will give a result that is less than pleasing to the eye. A properly matched hardcoat is very important for this reason.

In summary, when choosing the lens and the hardcoat to match with a thin film (AR or mirror) coating, use this information to help to make your decision. To provide the best product to your customer and the best performance over the life of the prescription, pair the thick film and the thin film together correctly; this will help the marriage last.