While at a teaching seminar recently, I was discussing AR coatings and their properties relative to different types of lenses. I spoke about refractive index and the effects of index on thin films. This was fairly novel, so I thought I would take the time to discuss it.

There are several different effects that refractive indexes have relative to coatings. One that I have previously discussed is the stress in the lens relative to the lens type. https://qtmi.net/is-your-ar-coating-stressed-out/. This is an important property and one that everyone should thoroughly understand when making choices or claims relative to coatings. But, in this discussion I would like to solve/resolve the question that came up at the seminar. Why is the color on the front side of the lens different from the color on the backside of the lens? Or, another common question, why is the color on Poly different from CR39 and, again, different on Hi Index.

In the blog, https://qtmi.net/anti-reflective-coatingare-we-looking-at-this-wrong/, I really went deep into the theory of an AR coating and what is happening to light. I didn’t take into account the phenomenon of a varying refractive index to start with. Let’s take a look at the basic math surrounding light hitting a surface. This is an excerpt from an earlier blog.

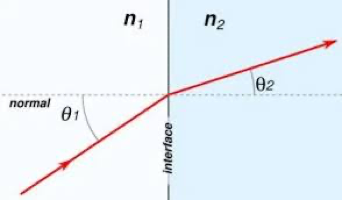

When the light meets the interface at normal incidence (perpendicularly to the surface), the intensity of light reflected is given by the reflection coefficient or reflectance, R:

Where n0 and nS are the refractive indices of the first and second media, respectively. The value of R varies from 0 (no reflection) to 1 (all light reflected) and is usually quoted as a percentage. Complementary to R is the transmission coefficient or transmittance, T. If absorption and scattering are neglected, then the value T is always 1–R. Thus, if a beam of light with intensity I is incident on the surface, a beam of intensity RI is reflected, and a beam with intensity TI is transmitted into the medium.

For the simplified scenario of visible light traveling from air (n0≈1.0) into common glass (nS ≈ 1.5), value of R is 0.04, or 4% on a single reflection. So at most 96% of the light (T = 1 − R = 0.96) actually enters the glass, and the rest is reflected from the surface. The amount of light reflected is known as the reflection loss.,

In the above equation, the refractive index is extremely important when calculating the reflection. The refractive indexes of the materials in the equation are what allow you to calculate the reflection percentage. If a refractive index is varied, the reflection is varied.

This seems pretty straightforward and most people get this relative to the lens. What people forget is that this same phenomenon is happening for EVERY surface the light comes in contact with. This is true for each layer of the AR coating, the Super Hydrophobic, the hardcoat and the lens. So, if an AR coating (or any coating for that matter) is created and calculated for a specific index, it will not work the same if the index is varied.

A very common example of this is to have a semi-finished lens with a factory hardcoat on the convex side of the lens and a UV spin hardcoat on the backside of the lens. It could be that these hardcoats exactly match (refractive index), but that is most likely not the case. So, the result is a shift in the reflection of the AR coating. This is true for all index shifts. This is just the physics of it.

In this example, this is the same AR coating applied to 2 different lens types. The AR coating stayed exactly the same. But, as you can see, the color is different from lens to lens. The solid line will be more green-blue and the dashed line will be more green-yellow.

The only way around this effect is to have the AR coating matched to the index of the hardcoat and lens combination. In most American AR coating labs, this is not possible due to the number of AR coating jobs and the fact that the labs are “batching” their work. These “batches” consists of many varying indexes all getting the same AR coating. Couple that with the fact that most American labs do not dip hardcoat, and this leads to varying indexes on the convex and concave side of the lens. The results (color), not surprisingly, are varied.