To effectively produce top quality coatings as well as understand the reasons for adherence to standard best practices, it is beneficial to recognize the complexities behind anti-reflective (AR) coatings and how they function. This is a brief summary of light and the basic principles by which thin film anti-reflective coatings work.

Interference

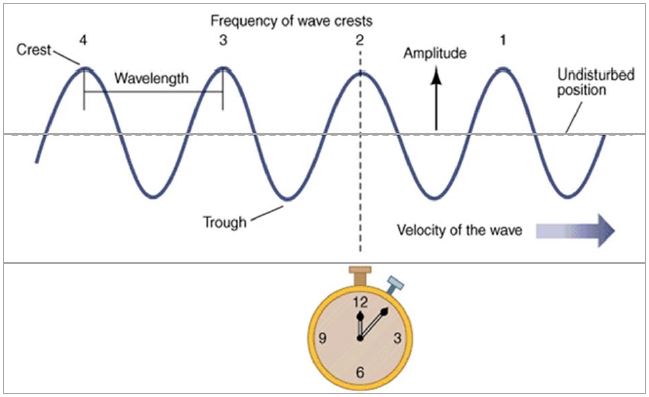

Light moves in waves. The construction of the movement consists of crests and troughs. A wavelength is the distance from the top of one crest to the top of the next crest.

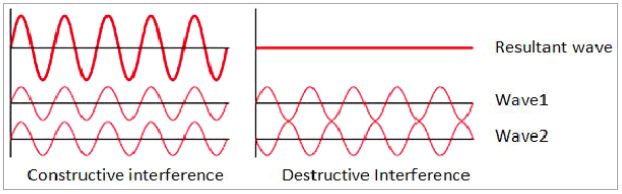

AR works on the principle of light wave interference. One type of wave interference is Constructive Interference, where the crests and troughs move together and enhance each other.

Another type of interference is Destructive Interference, where the crests and troughs move opposite each other. When movement of light from the coating is ½ a wavelength out of sync with the movement of light from the lens, the crests of the coating move with the troughs of the lens. The two wavelengths cancel each other out and there is no reflection.

Elements of an AR Coating

Hardcoat

A critical component of any anti-reflective treatment is the hardcoat. This is the first layer applied to a lens surface. The hard coat provides bonding of the AR layers to the lens surface. The overall quality of the AR treatment depends in large part on the quality of the hardcoat layer. Higher quality hardcoats are matched to specific lens materials for optimum adhesion, durability and stability.

When the index of refraction of the hardcoat matches that of the lens material, reflections are minimized. If the index of refractions of the lens and the coating don’t match, birefringence occurs.

Birefringence is reflection off both the lens surface and the hardcoat, producing a rainbow effect on the front of the lens. If the coating and lens have the same index of refraction, light passes through as though the lens and the hardcoat were one material. This reduces reflections.

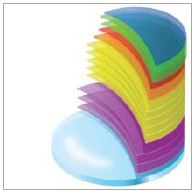

AR Stack

The AR coating is made up of a stack of alternating layers of high refractive index and low refractive index materials. The AR layers are responsible for creating the destructive interference patterns needed to knock out lens surface reflections.

Oleophobic

Premium ARs have an oleophobic treatment as the outside layer of their AR coating. The purpose of this layer is to repel grease and oil, making the lenses easier to clean. This topcoat is also very slick, allowing the cleaning cloth to slide over the lens with less chance of scratching. The oleophobic quality proves its worth with the touch of a finger. The higher the quality of this layer, the less oil is deposited on the lens when it is touched.

Hydrophobic/Oleophobic

Premium Plus ARs have hydrophobic/oleophobic properties as their topcoat. This treatment causes water to bead up on the lenses so most of it can be shaken off and the lenses can be gently patted dry.

The hydrophobic/oleophobic treatment seals and protects the AR layers. It also acts as an abrasion-resistant coating, protecting the lens from the assault of cleaning and constant use. This outer layer does not render the lenses scratch-proof, but it is very scratch-resistant.

Anti-Static Properties

Anti-static properties allow the lenses to dissipate electric charges and prevent charge buildup. It helps keep dust and other airborne particles from clinging to the lenses. Without anti-static properties, static electricity builds up, causing the lenses to attract the dust and particles. Wiping them becomes an exercise in futility – much like wiping a TV screen with a dry cloth. The cloth just chases the dust.

UVAR

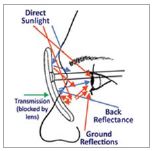

UV protection from the frontside of the lens can be provided by the lens itself, depending upon material chosen. Polycarbonate, High Index Plastics and Trivex lenses absorb the UV from the frontside. The backside of the lens is a different story, as there will be UV reflected from the backside of the lens into the wearer’s eye. A UVAR coating added to the backside can transmit this UV light through the lens and away from the wearer’s eye, increasing both safety and clarity of vision.

Benefits of Anti-Reflective Coatings

Coating Benefits

- Increased Light Transmission – The light that is reflected off non-coated lenses is passed through AR coated lenses, making vision sharper and clearer.

- Reduced Eyestrain – AR reduces glare from computer screens and reflections from the sides and back of lenses, resulting in less competition with reflections and more comfortable viewing.

- Better Night Vision – Reflections and glare are reduced, making night vision sharper to improve night driving.

- Cosmetics – AR allows the eyes to show bright and clear to others, without the detraction of room reflections.

Lenses that Benefit from AR

- Hi Index – Transmit less light than lenses of lower index because they are highly reflective. AR treatment can increase light transmission to 99%. AR should always be recommended with high index lenses.

- Aspheric – Often made in high index materials and they have a flatter profile than nonaspheric lenses. Backside reflections are increased because of the flatter surface. This combination of features makes aspheric lenses excellent candidates for AR treatment.

- Dress Eyewear – Because anti-reflective coating increases light transmission, dress eyewear benefits from AR treatment. Vision in all light levels is enhanced, especially in low-level lighting, such as theaters, restaurants, churches.

- Specialty Eyewear – Such as for computer work, hobbies or sports, these benefit from AR treatment because of the sharp, clear vision it produces.

- Sunwear – The tint on sunwear can make the lenses more reflective. A backside AR reduces reflections off the back of the lens while the front of the lenses maintains its ray-blocking properties.